OUR PRODUCTS CATEGORY

Discover our collections and get inspired!

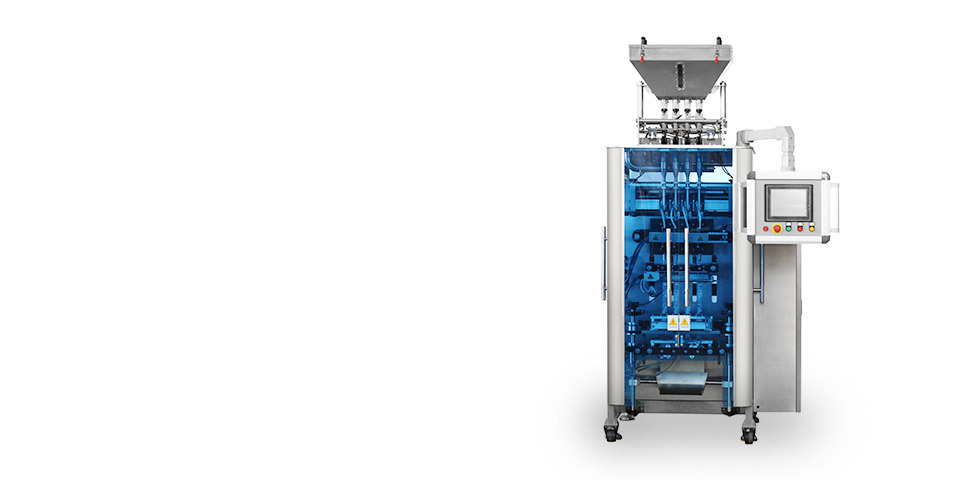

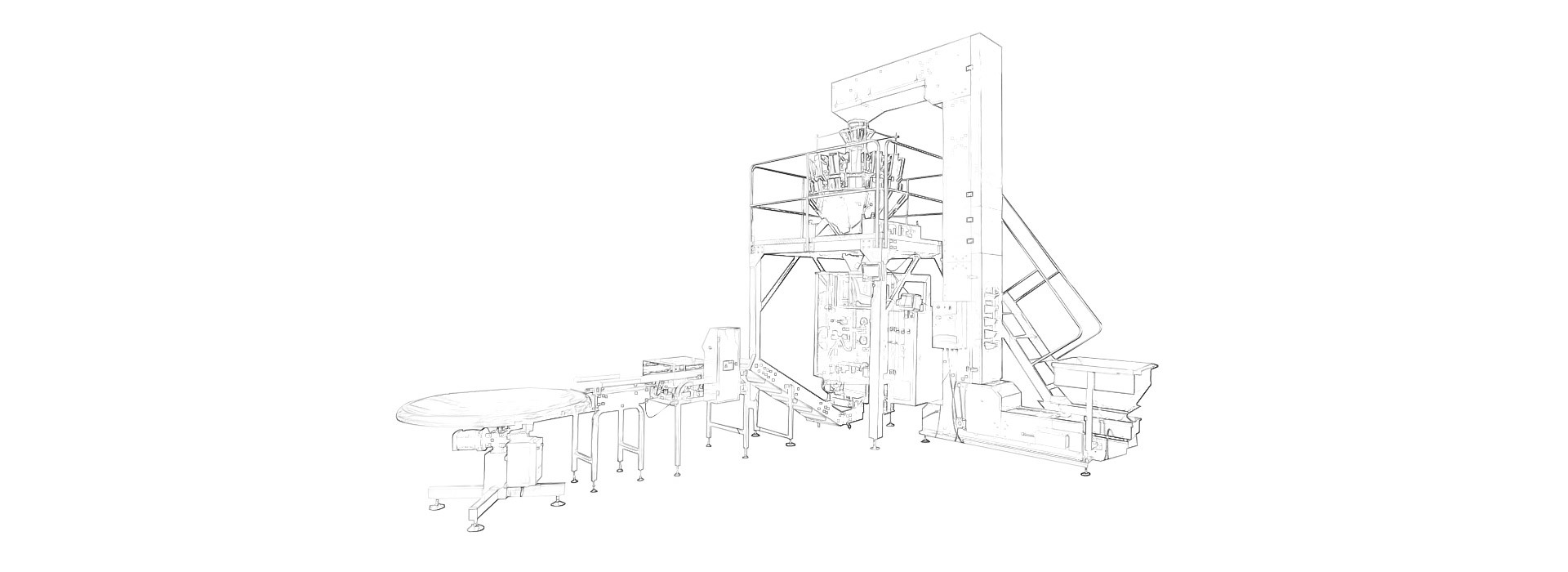

Vertical Form Film Seal Packing Machine

Vertical Film Automatic Snack Sealing Packaging Machine Sales Price Equipment Specifications and Functions: The prices of vertical film automatic snack sealing packaging machines with different specifications and functions will vary.

Premade Pouch Packing Machine

The automatic bag packing machine is an efficient and intelligent mechanical equipment that can greatly improve packaging efficiency and product quality.

Stick pack&sachet packing machine

Automatic Stick Packaging and Pouch Packaging Machine Manufacturers and Suppliers offer a diverse product line and high quality products.

Doser

China is one of the largest feeder suppliers and wholesalers in the world, with numerous factories and suppliers. A feeder is a mechanical device used to add additives

OUR SOLUTION

Building a better future with packaging solutions.

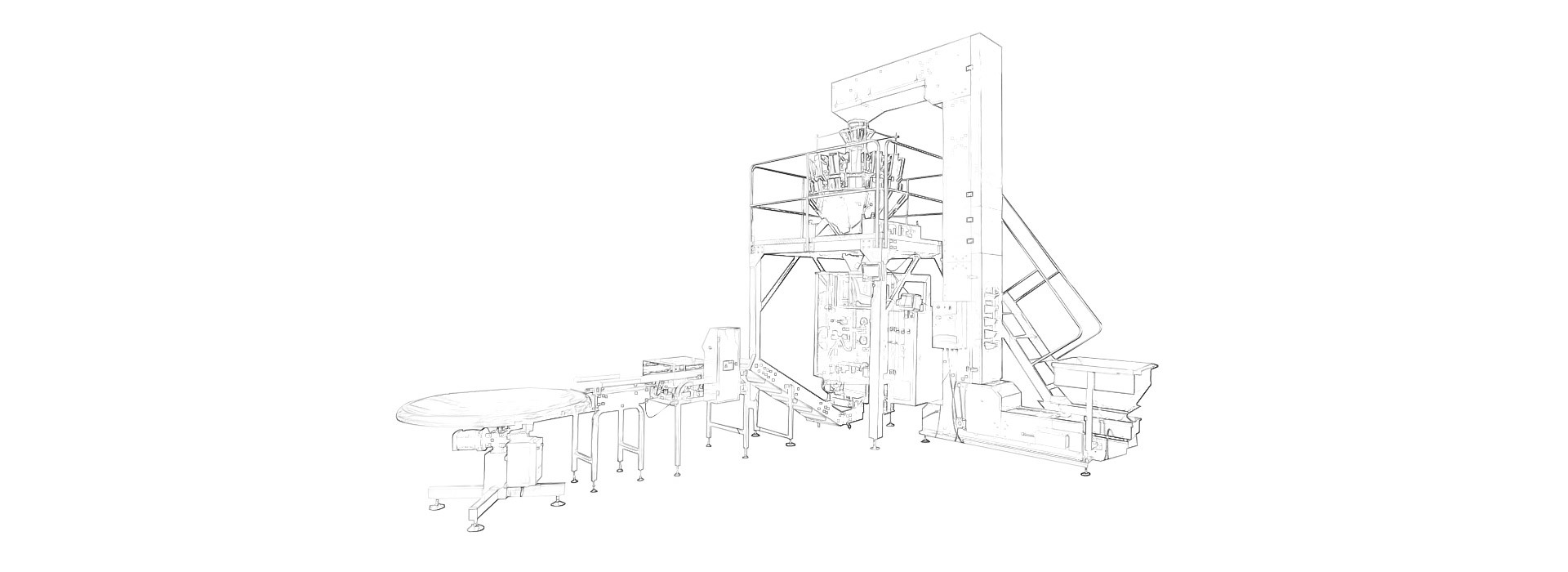

OUR PRODUCTION LINE DESCRIPTION

Automatic Weighing,Packing,Checking & Detecting

FACTORY TOUR

Behind-the-scenes insights into production and innovation.

Foshan Wilpac Packaging Machinery Co., Ltd. is located in Foshan.So far, our packaging machinery is sold to Europe, America, the Middle East and Southeast Asia etc.Our performance and quality is widely accepted and praised by our customers.We take "Innovative Technology, Optimal Management, Service Integrity, Market Development" as our philosophy.We adhere to the company tenet of "technology first, the market as guide, quality is fundamental, reputation is guarantee".

Year Of Established

➕Thousands Cumulative Sales

➕Countries We Have Sold To

Qualification Patents

LATEST NEWS

Stay informed with the freshest updates.